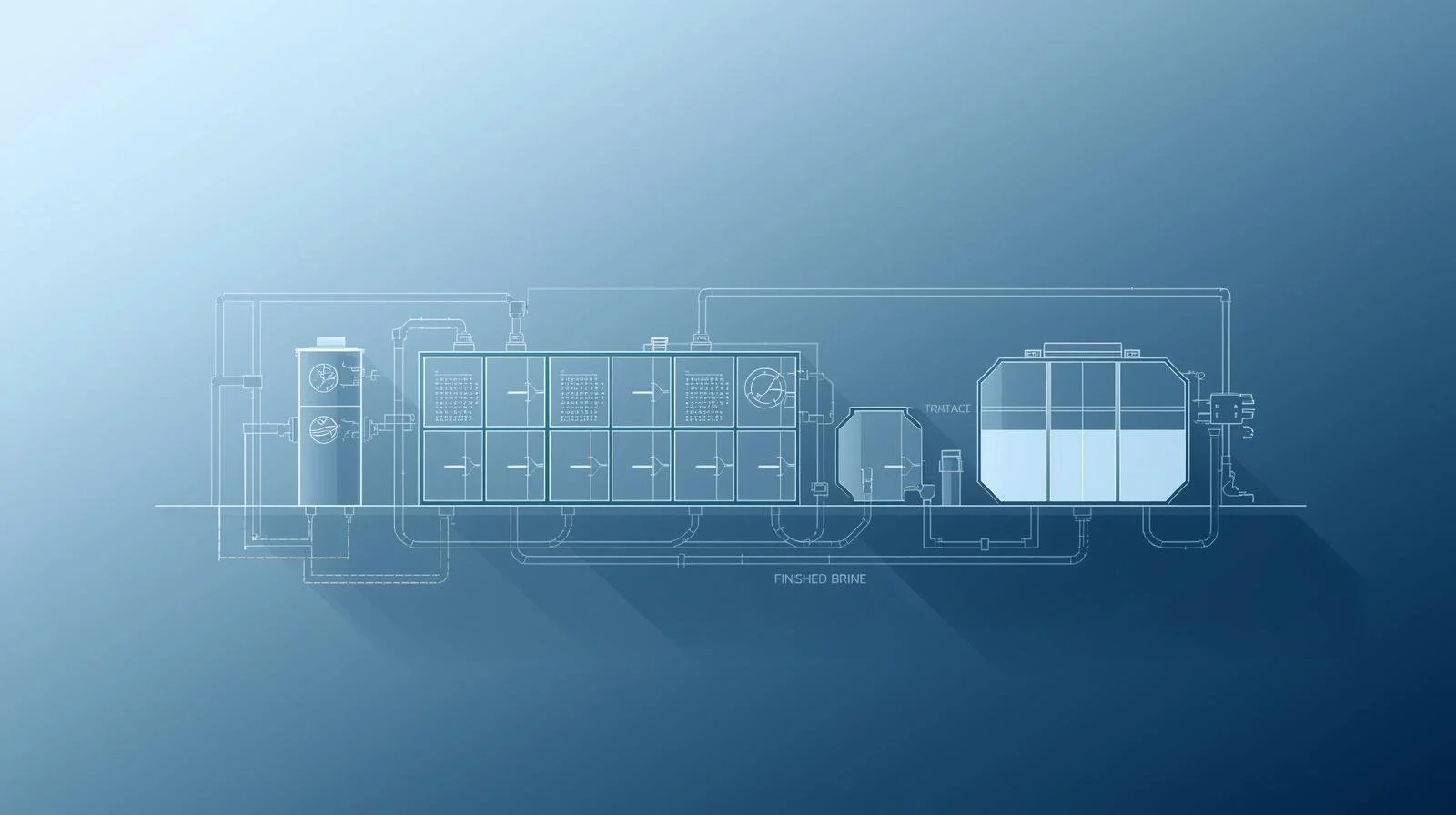

NP-KR Modular Water-Reuse Platform

A near-term modular water-reuse system engineered to reduce operational headaches and deliver predictable water quality for industrial and energy operators

Operators today face inconsistent water quality, high disposal costs, and logistical complexity. NP-KR is designed as a flexible, vendor-aligned platform that adapts to different water-quality goals while supporting future local fabrication in Western Pennsylvania.

Two Variants, One Modular Platform

NP-KR is built around a shared architecture with two distinct configurations depending on operator needs

NP-KR (Brine-Ready Variant-Oil & Gas Focus)

The primary configuration engineered for upstream and midstream operators. This variant produces finished brine suitable for reuse, blending, or storage, while dramatically reducing solids-related headaches

Ideal For:

-frac operations

-produced-water reuse

-pad-level or regional treatment

-operators seeking predictable water without over-treating

Outputs:

-finished brine

-concentrated solids stream

NP-KR ZLD (Zero-Liquid Discharge Variant)

A higher-temperature, higher efficiency configuration designed to remove essentially all solids, producing a dry or near-dry output

Ideal For:

-industrial users

-regions with strict disposal limits

operators seeking minimal liquid waste

log-term manufacturing and ceramics integration

Outputs:

-dry solids

-minimal or zero liquid residual

Shared Advantages Across Both Variants

-modular, vendor-aligned architecture

surge-tolerant design

-predictable water quality

-reduced trucking and disposal

Development Status

NP-KR is an early-stage engineering concept under active development, with a focus on aligning design, fabrication, and testing with regional partners and Western Pennsylvania’s advanced-manufacturing ecosystem.

Adaptive Cone-Coil Overshot

A patent-pending fishing tool concept engineered for improved reliability and adaptability in downhole recovery operations.

Traditional overshots struggle with inconsistent engagement, tool slippage, and unpredictable retrieval performance. The Adaptive Cone-Coil Overshot is designed to address these challenges through a more forgiving, surge-tolerant interface that maintains grip under variable downhole conditions.

The Overshot is engineered to continuously catch across a broad diameter span, eliminating the need for multiple fixed-size assemblies.

Designed Catch Window:

1.25”-3.125”

This adaptive range covers the vast majority of coil tubing and production tubing retrieval scenarios without swapping tools or inserts.

Continuous Catch Range

What It Solves

-unreliable engagement with coil or tubulars

-tool slippage during retrieval

-inconsistent performance across well conditions

-high downtime and repeated fishing attempts

Key Advantages

-adaptive cone-coil interface for improved capture

-reduced risk of tool failure or partial engagement

-modular catch assemblies for multiple diameters

-supports faster, more predictable fishing operations

Development Approach

Neuratherm Power Systems focuses on design, IP development, and engineering refinement, while fabrication and field-testing are expected to be performed by regional partners. This approach strengthens Western Pennsylvania’s energy-services sector and accelerates the path from concept to field-ready prototype.

Neuratherm Power Systems focuses on design, IP development, and engineering refinement, while fabrication and field-testing are expected to be performed by regional partners. This approach strengthens Western Pennsylvania’s energy-services sector and accelerates the path from concept to field-ready prototype.

Status

The Adaptive Cone-Coil Overshot is an early-stage engineering concept currently undergoing design refinement and partner alignment for prototype fabrication.

NeuraCore Thermal Energy Platform

A long‑term ceramic‑manifold thermal‑storage concept designed to capture high‑temperature waste heat and convert it into usable power and thermal output.

Industrial facilities, data centers, and next‑generation energy systems generate enormous amounts of high‑grade heat that is typically wasted. NeuraCore explores how advanced ceramics, modular manifolds, and controlled heat‑flow pathways can store and redistribute that energy for meaningful industrial use.

This platform represents the future of thermal‑energy innovation and the foundation for a new advanced‑manufacturing cluster in Western Pennsylvania.

What NeuraCore Aims to Solve

-loss of high‑temperature waste heat

-inefficient thermal‑management systems

-lack of scalable, modular thermal‑storage options

-limited domestic manufacturing of advanced ceramic components

Core Concept

NeuraCore centers on a high‑temperature ceramic manifold engineered to:

-absorb and store heat from industrial or energy‑sector sources

-release that heat in a controlled, predictable manner

-integrate with power‑generation or thermal‑management systems

-support modular scaling from pilot units to industrial arrays

The concept leverages ceramics, robotics, machining, and thermal‑systems engineering — all strengths of the Western PA ecosystem.

Potential Applications

-industrial heat‑recovery systems

-data‑center thermal management

-nuclear uprate support

-distributed thermal‑energy storage

-high‑temperature process industries

Regional Impact

As NeuraCore matures, it creates opportunities for:

-ceramic manufacturing

-precision machining

-robotics and automation

-advanced‑materials research

-long‑term job creation in Western Pennsylvania

This platform is designed not just as a technology, but as a future anchor for regional advanced manufacturing.

Development Status

NeuraCore is a long‑term engineering concept in early‑stage modeling and materials exploration. Future phases include ceramic‑manifold prototyping, heat‑flow testing, and alignment with regional manufacturing partners.